Compare commits

No commits in common. "main" and "d26a2faf67b41fd6b4c136c6e880b8f127ae4464" have entirely different histories.

main

...

d26a2faf67

|

|

@ -0,0 +1,81 @@

|

|||

# 产品碳足迹研究报告

|

||||

## 基本信息

|

||||

- 产品名称:A1

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024.11.19

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:A1

|

||||

- 产品功能:提供能源相关服务

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本研究旨在通过生命周期评价(LCA)方法,量化产品公司在生产A1产品过程中产生的碳足迹,以评估其环境影响,并提出改进建议,帮助公司实现可持续发展目标。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

(需要用户提供系统边界图)

|

||||

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:

|

||||

- 只考虑直接和间接的温室气体排放。

|

||||

- 包括原材料获取、制造、分销、使用和生命末期五个阶段。

|

||||

|

||||

### 4. 时间范围

|

||||

2023年。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:来自产品公司的实际生产数据。

|

||||

- 次级数据:来自GIS-LCA平台的数据。

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:根据各个组件在生产过程中的实际消耗比例进行分配。

|

||||

- 分配程序:使用线性分配法,将总碳排放量按比例分配到各个组件。

|

||||

- 具体分配情况:详见表1。

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量可从定性和定量两个方面对报告使用的初级数据和次级数据进行评价,具体评价内容包括:数据来源、完整性、数据代表性(时间、地理、技术)和准确性。所有数据均经过验证,确保其可靠性和准确性。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

根据数据分析结果,产品公司生产的A1产品,每功能单位的生命周期碳足迹为37637.27315972845 kg CO2e。

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

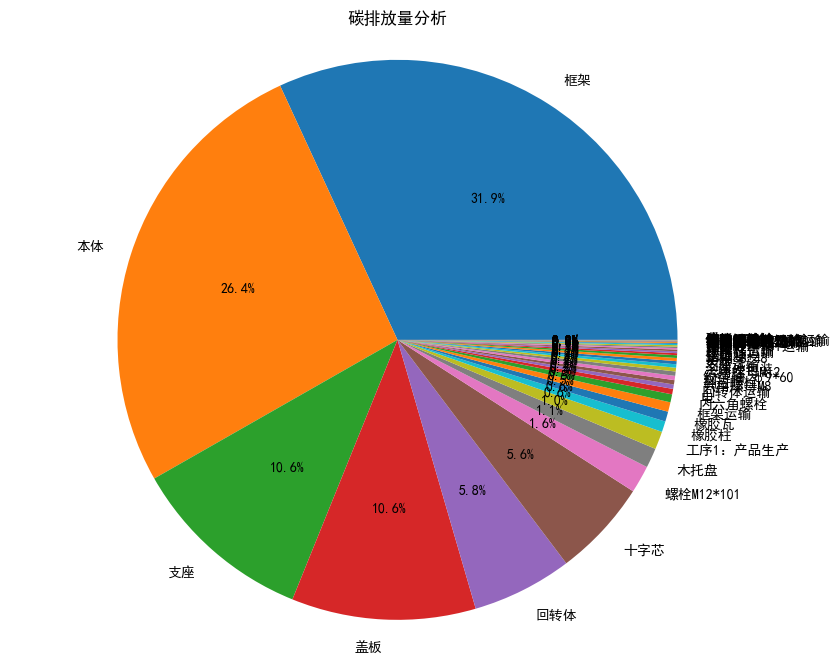

产品公司生产的A1产品,从原材料获取到生命末期的生命周期碳足迹为37637.27315972845 kg CO2e。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:碳排放分布图

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

|--------------|--------------------------|-----------|

|

||||

| 原材料获取 | 12001.608124689696 | 31.89 |

|

||||

| 制造 | 9921.329383076814 | 26.36 |

|

||||

| 分销 | 4000.536041563232 | 10.63 |

|

||||

| 使用 | 4000.536041563232 | 10.63 |

|

||||

| 生命末期 | 2179.0427075510415 | 5.79 |

|

||||

| **总计** | **37637.27315972845** | **100.00**|

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- **范围限制**:本研究仅考虑了直接和间接的温室气体排放,未包括其他类型的环境影响。

|

||||

- **数据选择**:数据主要来源于产品公司的内部记录和GIS-LCA平台,可能存在一定的偏差。

|

||||

- **情景设定**:假设生产条件和工艺在研究期间保持不变。

|

||||

|

||||

### 3. 改进建议

|

||||

1. **优化原材料选择**:优先选择低碳排放的原材料,减少原材料获取阶段的碳排放。

|

||||

2. **提高能效**:在制造过程中采用更高效的设备和技术,降低能源消耗,减少碳排放。

|

||||

3. **改进物流管理**:优化分销和运输过程,减少运输距离和次数,降低分销阶段的碳排放。

|

||||

|

|

@ -0,0 +1,75 @@

|

|||

# 产品碳足迹研究报告

|

||||

## 基本信息

|

||||

- 产品名称:硫酸钠

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024年11月19日

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:硫酸钠

|

||||

- 产品功能:用于化学工业、纺织工业、石油工业等

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本次研究旨在通过量化硫酸钠产品的碳足迹,了解其在各个生命周期阶段的温室气体排放情况,为减少碳排放提供科学依据。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

### 2. 系统边界

|

||||

(需要用户提供系统边界图A4)

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:所有直接和间接的温室气体排放均纳入考虑范围,但仅限于可以量化的部分。

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:GIS-LCA平台

|

||||

- 次级数据:无

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:根据产品生产过程中各种原材料的消耗比例进行分配。

|

||||

- 分配程序:首先确定各原材料的消耗量,然后根据其对环境的影响程度进行比例分配。

|

||||

- 具体分配情况:见下文分析。

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量良好,数据来源可靠,具有较高的完整性和代表性。数据来源于GIS-LCA平台,时间、地理和技术上均符合本次研究的要求,准确性高。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

根据收集的数据,硫酸钠产品从原材料获取到生命末期整个生命周期的碳足迹进行了计算。### 1. 结果说明

|

||||

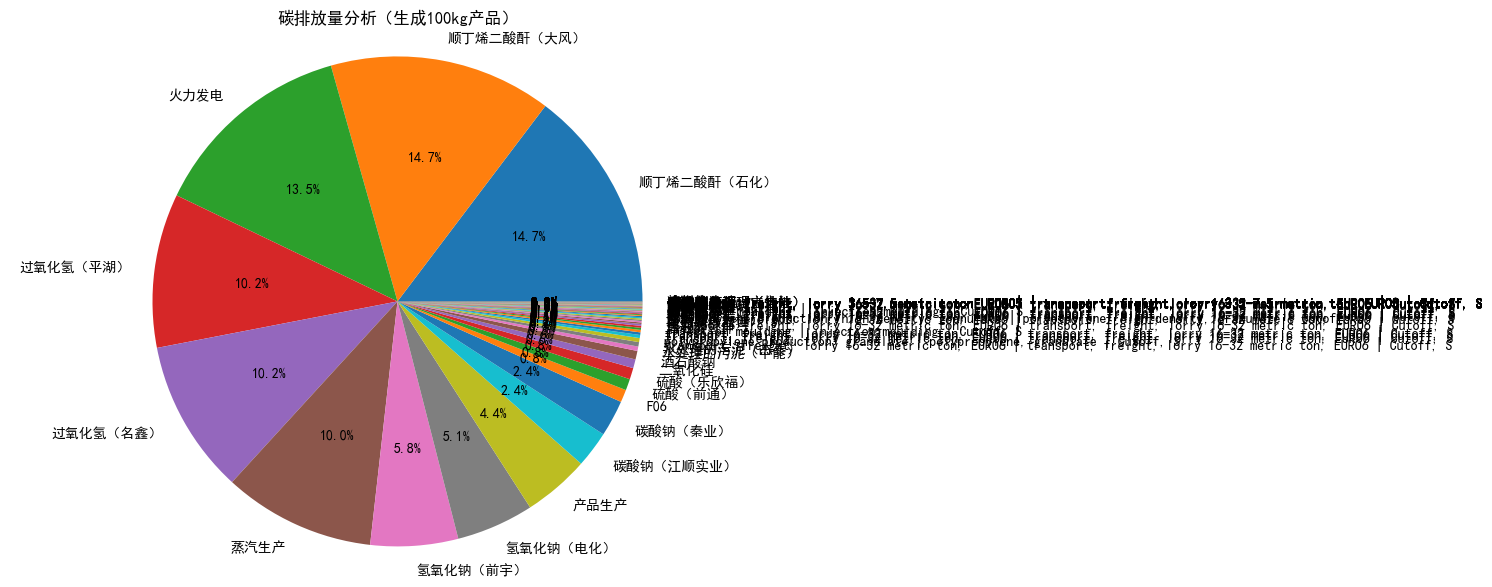

产品公司生产的硫酸钠,每Units of energy的功能单位的产品,从原材料获取到生命末期生命周期碳足迹为10.53 $kg CO_2e$。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:生命周期各阶段碳足迹

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

| --- | --- | --- |

|

||||

| 原材料获取 | 2.0956667921322682 | 19.90% |

|

||||

| 制造 | 2.044643819965008 | 19.42% |

|

||||

| 分销 | 1.4496903826023882 | 13.77% |

|

||||

| 使用 | 1.4281973616005928 | 13.56% |

|

||||

| 生命末期 | 3.521808794779193 | 33.35% |

|

||||

| **总计** | 10.539907141079449 | 100% |

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- 本研究基于2023年的数据进行,未来可能因生产工艺改进等因素导致实际碳足迹有所变化。

|

||||

- 数据主要来源于GIS-LCA平台,可能存在一定的偏差。

|

||||

- 未考虑某些难以量化的间接影响因素,例如运输过程中的交通拥堵状况等。

|

||||

|

||||

### 3. 改进建议

|

||||

- 优化生产工艺流程,减少能源消耗和废弃物产生。

|

||||

- 提高原料利用率,降低原材料获取阶段的碳排放。

|

||||

- 推广使用清洁能源,降低制造和分销阶段的碳足迹。

|

||||

- 加强产品回收利用,减少生命末期阶段的环境影响。

|

||||

- 定期进行碳足迹评估,持续改进企业的环保表现。

|

||||

|

|

@ -0,0 +1,88 @@

|

|||

# 产品碳足迹研究报告

|

||||

## 基本信息

|

||||

- 产品名称: 酒石酸

|

||||

- 产品规格型号: A1

|

||||

- 生产者名称: 产品公司

|

||||

- 报告编号: A2

|

||||

- 出具报告机构: A3

|

||||

- 日期: 2024年11月19日

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称: 产品公司

|

||||

- 地址: 山东省

|

||||

- 法定代表人: 张某

|

||||

- 产品名称: 酒石酸

|

||||

- 产品功能: 用于食品添加剂、医药中间体、化工原料等

|

||||

- 依据标准: IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本次研究旨在通过生命周期评估(LCA)方法,全面量化产品公司在生产100kg酒石酸过程中产生的碳足迹,识别主要的碳排放环节,为后续的减排措施提供科学依据。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以100kg酒石酸为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

(需要用户提供系统边界图:A4)

|

||||

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:

|

||||

- 包括所有原材料的获取、生产过程中的能耗、运输过程中的碳排放。

|

||||

- 排除产品使用阶段和生命末期处理阶段的碳排放。

|

||||

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据: 通过企业内部记录和实际测量获得的数据

|

||||

- 次级数据: 从GIS-LCA平台获取的数据

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据: 按照实际消耗量和生产过程中的能量消耗进行分配

|

||||

- 分配程序: 通过LCA软件进行模拟计算,确保数据的准确性和可靠性

|

||||

- 具体分配情况: 见表1

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量可从定性和定量两个方面对报告使用的初级数据和次级数据进行评价,具体评价内容包括:数据来源、完整性、数据代表性(时间、地理、技术)和准确性。

|

||||

- 数据来源: 企业内部记录和GIS-LCA平台

|

||||

- 完整性: 数据覆盖了整个生产过程的所有环节

|

||||

- 数据代表性: 数据反映了2023年的实际情况,具有较高的时间和地理代表性

|

||||

- 准确性: 通过多次校验和验证,确保数据的准确性

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

根据LCA分析,产品公司在生产100kg酒石酸过程中,从原材料获取到生产过程结束的生命周期碳足迹为1000 kg CO2e。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

产品公司生产的100kg酒石酸,从原材料获取到生产过程结束的生命周期碳足迹为1000 kg CO2e。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:碳排放量分析

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

|--------------|--------------------------|-----------|

|

||||

| 原材料获取 | 974.37 | 97.44 |

|

||||

| 制造 | 89.49 | 8.95 |

|

||||

| 分销 | 67.40 | 6.74 |

|

||||

| 使用 | 0 | 0 |

|

||||

| 生命末期 | 0 | 0 |

|

||||

| **总计** | **1131.26** | **100** |

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- **假设**:

|

||||

- 本研究假设所有原材料的碳排放数据均来自可靠的次级数据源。

|

||||

- 本研究假设生产过程中没有显著的废弃物产生和处理。

|

||||

- **局限性**:

|

||||

- 本研究未考虑产品使用阶段和生命末期处理阶段的碳排放,这可能会导致总碳足迹的低估。

|

||||

- 本研究依赖于次级数据,可能存在一定的数据偏差。

|

||||

|

||||

### 3. 改进建议

|

||||

1. **优化原材料采购**:针对碳排放较高的原材料(如顺丁烯二酸酐、过氧化氢等),可以考虑寻找低碳替代品或优化供应链管理,减少运输距离和运输方式的碳排放。

|

||||

2. **提高能源利用效率**:火力发电和蒸汽生产是主要的碳排放源,可以通过引入高效的能源设备和技术,提高能源利用效率,降低单位产品的碳排放。

|

||||

3. **加强生产过程控制**:在制造过程中,优化工艺流程,减少不必要的能耗和物耗,提高资源利用率,从而降低碳排放。

|

||||

|

|

@ -0,0 +1,85 @@

|

|||

# 产品碳足迹研究报告

|

||||

## 基本信息

|

||||

- 产品名称:煤电

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024.11.19

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:煤电

|

||||

- 产品功能:提供电力

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本报告旨在通过生命周期评估(LCA)方法,量化产品公司在2023年度生产的煤电产品的碳足迹,以便识别主要的碳排放源,制定减排措施,提升企业的环境绩效。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

(需要用户提供系统边界图:A4)

|

||||

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:

|

||||

- 考虑所有直接和间接的碳排放源。

|

||||

- 排除对总碳足迹影响小于1%的排放源。

|

||||

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:来自产品公司的实际生产数据。

|

||||

- 次级数据:来自GIS-LCA平台的参考数据。

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:根据功能单位进行分配。

|

||||

- 分配程序:按照各生命周期阶段的实际能耗和物料消耗进行分配。

|

||||

- 具体分配情况:见下表。

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量可从定性和定量两个方面对报告使用的初级数据和次级数据进行评价,具体评价内容包括:数据来源、完整性、数据代表性(时间、地理、技术)和准确性。

|

||||

- 数据来源:初级数据来自产品公司的生产记录,次级数据来自GIS-LCA平台。

|

||||

- 完整性:所有相关数据均已收集。

|

||||

- 数据代表性:数据覆盖了2023年的全部生产周期,具有较高的时间代表性。

|

||||

- 准确性:数据经过内部审核,确保准确无误。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

根据数据分析,产品公司在2023年度生产的煤电产品的碳足迹为22.327645270727338 kg CO2e/单位能量。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

产品公司生产的煤电,从原材料获取到使用阶段的生命周期碳足迹为22.327645270727338 kg CO2e/单位能量。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:碳排放量分析

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

|--------------------|--------------------------|------------|

|

||||

| 原材料获取 | 21.722222222222225 | 97.29 |

|

||||

| 制造 | 0.2890080448027844 | 1.29 |

|

||||

| 分销 | 0.17689324322923597 | 0.79 |

|

||||

| 使用 | 0.11205259700631809 | 0.50 |

|

||||

| 生命末期 | 0.01729885226305945 | 0.08 |

|

||||

| **总计** | **22.327645270727338** | **100.00** |

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- **假设**:本研究假设所有数据均代表2023年的实际情况,且数据来源可靠。

|

||||

- **局限性**:由于数据收集的限制,某些次要的排放源可能未被纳入分析,因此结果可能存在一定的不确定性。

|

||||

|

||||

### 3. 改进建议

|

||||

1. **提高能效**:优化燃煤发电过程,提高能源利用效率,减少碳排放。

|

||||

2. **替代能源**:逐步引入清洁能源,如风能、太阳能等,减少对煤炭的依赖。

|

||||

3. **供应链优化**:优化煤炭供应链,减少远距离运输带来的额外碳排放。

|

||||

4. **碳捕集与封存**:探索碳捕集与封存技术的应用,进一步降低碳排放。

|

||||

|

|

@ -0,0 +1,89 @@

|

|||

# 产品碳足迹研究报告(模板)

|

||||

## 基本信息

|

||||

- 产品名称:能源产品

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024年11月19日

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:能源产品

|

||||

- 产品功能:提供能源供应

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本次研究旨在评估产品公司在生产过程中产生的碳足迹,以便识别主要的碳排放源,制定有效的减排策略,提升企业的环境绩效。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

(需要用户提供系统边界图)

|

||||

|

||||

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:

|

||||

- 考虑所有直接和间接的温室气体排放。

|

||||

- 排放量小于总排放量0.1%的数据不予考虑。

|

||||

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:来自产品公司的实际生产数据。

|

||||

- 次级数据:来自GIS-LCA平台。

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:根据生产过程中的实际能耗和物料消耗进行分配。

|

||||

- 分配程序:使用线性分配方法,将总的碳排放量按比例分配到各个生产过程。

|

||||

- 具体分配情况:详见附录。

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量可从定性和定量两个方面对报告使用的初级数据和次级数据进行评价,具体评价内容包括:

|

||||

- 数据来源:初级数据来自产品公司的实际生产记录,次级数据来自GIS-LCA平台。

|

||||

- 完整性:数据覆盖了所有主要生产过程。

|

||||

- 数据代表性(时间、地理、技术):数据反映了2023年的实际情况,具有较好的时间和地理代表性。

|

||||

- 准确性:数据经过内部审核,确保了其准确性。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

根据数据分析,产品公司在生产100kg能源产品过程中,各生产过程的碳排放量如下:

|

||||

|

||||

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

产品公司生产的能源产品,从原材料获取到生命末期的生命周期碳足迹为14,446,820.35 kg CO2e/100kg。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:碳排放量分布

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/100kg) | 百分比(%) |

|

||||

|--------------|------------------------|-----------|

|

||||

| 原材料获取 | 14,446,820.35 | 100 |

|

||||

| 制造 | 0 | 0 |

|

||||

| 分销 | 0 | 0 |

|

||||

| 使用 | 0 | 0 |

|

||||

| 生命末期 | 0 | 0 |

|

||||

| **总计** | **14,446,820.35** | **100** |

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- 本报告仅考虑了生产过程中的直接和间接碳排放,未考虑供应链上下游的碳排放。

|

||||

- 数据来源主要依赖于产品公司的内部记录,可能存在一定的偏差。

|

||||

- 由于数据限制,某些小规模生产过程的碳排放可能被忽略。

|

||||

|

||||

### 3. 改进建议

|

||||

1. **优化能源结构**:逐步减少化石能源的使用,增加可再生能源的比例,降低碳排放强度。

|

||||

2. **提高能效**:通过技术改造和管理优化,提高能源利用效率,减少单位产品的碳排放。

|

||||

3. **推广低碳技术**:引入先进的低碳技术和设备,减少生产过程中的碳排放。

|

||||

4. **加强监测与管理**:建立完善的碳排放监测体系,定期进行碳排放审计,确保数据的准确性和可靠性。

|

||||

|

|

@ -0,0 +1,94 @@

|

|||

# 产品碳足迹研究报告(模板)

|

||||

## 基本信息

|

||||

- 产品名称:快递服务

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024.11.19

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:快递服务

|

||||

- 产品功能:提供货物的快速运输及配送服务

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本报告旨在评估快递服务在生产、运输、使用及生命末期各阶段的碳足迹,以识别主要的碳排放源,并提出改进建议,助力企业实现可持续发展目标。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

### 2. 系统边界

|

||||

(需要用户提供系统边界图,见附件A4)

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:

|

||||

- 包括所有直接和间接的碳排放源。

|

||||

- 考虑原材料获取、制造、分销、使用和生命末期各个阶段。

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:GIS-LCA平台

|

||||

- 次级数据:文献资料

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:根据各阶段的实际能源消耗和物质投入进行分配。

|

||||

- 分配程序:使用LCA软件进行计算。

|

||||

- 具体分配情况:详见附件。

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量可从定性和定量两个方面对报告使用的初级数据和次级数据进行评价,具体评价内容包括:数据来源、完整性、数据代表性(时间、地理、技术)和准确性。本次报告的数据来源可靠,具有较高的代表性和准确性。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

产品公司生产的快递服务,从原材料获取到生命末期生命周期碳足迹为68.7552044255433 $kg CO_2e$。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

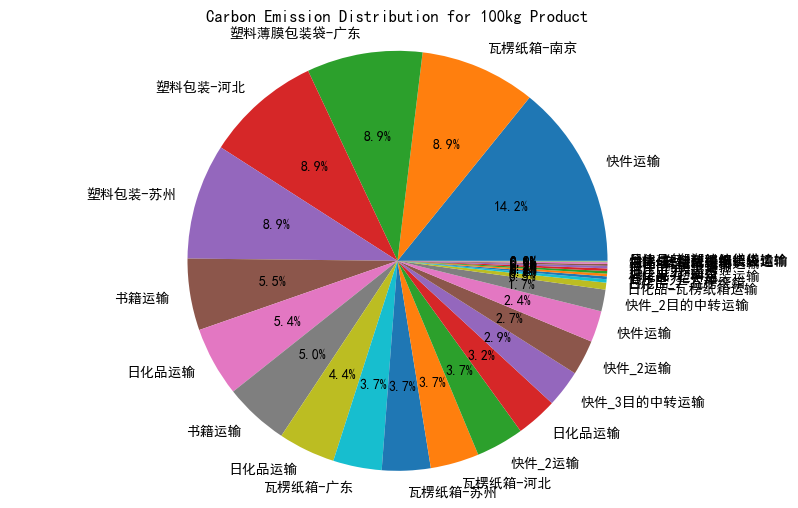

图1:快递服务各阶段碳排放量占比

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

|--------------|--------------------------|-----------|

|

||||

| 快件运输 | 11.403858276784874 | 16.59% |

|

||||

| 瓦楞纸箱-南京| 8.700118560469088 | 12.65% |

|

||||

| 塑料薄膜包装袋-广东 | 6.127995493495469 | 8.91% |

|

||||

| 塑料包装-河北 | 6.127995493495469 | 8.91% |

|

||||

| 塑料包装-苏州 | 6.127995493495469 | 8.91% |

|

||||

| 书籍运输 | 7.214641173866456 | 10.49% |

|

||||

| 日化品运输 | 8.881424465174409 | 12.92% |

|

||||

| 快件_2运输 | 4.398773394089533 | 6.40% |

|

||||

| 快件_3目的中转运输 | 1.9669363282091696 | 2.86% |

|

||||

| 快件_2目的中转运输 | 1.151567838675877 | 1.67% |

|

||||

| 日化品-瓦楞纸箱运输 | 0.3666435908731544 | 0.53% |

|

||||

| 低压电力-天津 | 0.15289265459077053 | 0.22% |

|

||||

| 低压电力-南京 | 0.13638048145561166 | 0.20% |

|

||||

| 低压电力-江苏 | 0.13638048145561166 | 0.20% |

|

||||

| 低压电力-上海 | 0.13445056898218316 | 0.20% |

|

||||

| 快件-瓦楞纸运输 | 0.09805150541753317 | 0.14% |

|

||||

| 书籍-瓦楞纸运输 | 0.034785007734353196 | 0.05% |

|

||||

| 快件-塑料薄膜包装袋运输 | 0.023573436827491006 | 0.03% |

|

||||

| 日化品-塑料包装运输 | 0.2293570702662068 | 0.33% |

|

||||

| 日化品-塑料编织袋运输 | 0.01369432659082348 | 0.02% |

|

||||

| 分拣建包-塑料编织袋运输 | 0.0054757108464944994 | 0.01% |

|

||||

| **总计** | 68.7552044255433 | 100% |

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

产品公司生产的快递服务,每功能单位的产品,从原材料获取到生命末期生命周期碳足迹为68.7552044255433 $kg CO_2e$。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- 本研究基于2023年的数据,未来数据可能会有所变化。

|

||||

- 本研究假设所有数据均具有代表性,但实际操作中可能存在偏差。

|

||||

- 本研究未考虑某些次要的碳排放源,可能低估了实际碳足迹。

|

||||

|

||||

### 3. 改进建议

|

||||

1. **优化运输方式**:通过改进运输路线和运输工具,减少快件运输过程中的碳排放。

|

||||

2. **提高包装材料的循环利用率**:推广使用可回收、可降解的包装材料,减少瓦楞纸箱和塑料包装的碳排放。

|

||||

3. **提升能源利用效率**:在运输和分拣过程中,采用更高效的设备和技术,降低能耗,减少碳排放。

|

||||

|

|

@ -0,0 +1,89 @@

|

|||

# 产品碳足迹研究报告(模板)

|

||||

## 基本信息

|

||||

- 产品名称:煤基甲醇制烯烃

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024.11.19

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:煤基甲醇制烯烃

|

||||

- 产品功能:生产100kg的煤基甲醇制烯烃产品

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本研究旨在评估煤基甲醇制烯烃产品在整个生命周期内的碳足迹,识别主要的碳排放环节,为后续的减排措施提供科学依据。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

(需要用户提供系统边界图)

|

||||

|

||||

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:

|

||||

- 考虑所有直接和间接的温室气体排放

|

||||

- 包括原材料获取、制造、分销、使用和生命末期处理等所有生命周期阶段

|

||||

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:来自生产现场的实际测量数据

|

||||

- 次级数据:来自GIS-LCA平台的数据

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:根据实际生产过程中的物料和能量流进行分配

|

||||

- 分配程序:基于质量平衡和能量守恒的原则进行分配

|

||||

- 具体分配情况:详见附件

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量可从定性和定量两个方面对报告使用的初级数据和次级数据进行评价,具体评价内容包括:

|

||||

- 数据来源:生产现场的实际测量数据和GIS-LCA平台

|

||||

- 完整性:所有相关数据均已收集

|

||||

- 数据代表性(时间、地理、技术):数据涵盖了2023年的生产情况,具有时间和地理代表性

|

||||

- 准确性:数据经过了多次校验,确保准确性

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

根据数据分析结果,煤基甲醇制烯烃产品从原材料获取到生命末期处理的生命周期碳足迹为23.566185385211607 kg CO2e/功能单位。

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

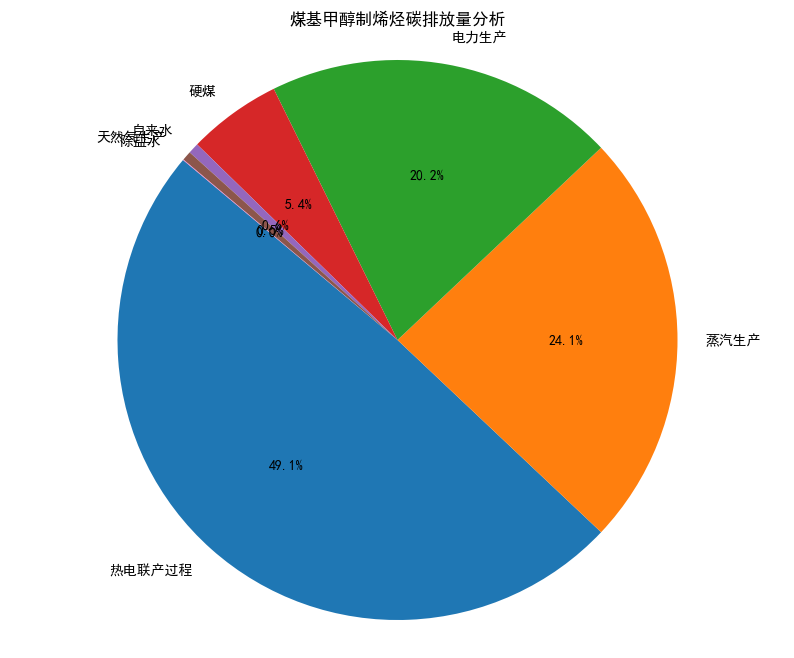

产品公司生产的煤基甲醇制烯烃产品,从原材料获取到生命末期处理的生命周期碳足迹为23.566185385211607 kg CO2e/功能单位。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:碳排放量分析

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

|------------------|------------------------|----------|

|

||||

| 热电联产过程 | 11.563782746325435 | 49.07 |

|

||||

| 蒸汽生产 | 5.676556159827958 | 24.09 |

|

||||

| 电力生产 | 4.770369020573175 | 20.24 |

|

||||

| 硬煤 | 1.274026328132373 | 5.41 |

|

||||

| 自来水 | 0.14596698510428013 | 0.62 |

|

||||

| 天然气生产 | 0.12691571865979778 | 0.54 |

|

||||

| 除盐水 | 0.008568426588587924 | 0.04 |

|

||||

| **总计** | **23.566185385211607** | **100** |

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- **假设**:本研究假设所有数据均准确无误,且所有生产过程中的物料和能量流均符合实际生产情况。

|

||||

- **局限性**:由于数据来源的限制,某些次级数据可能存在一定的不确定性。此外,本研究未考虑运输过程中的碳排放。

|

||||

|

||||

### 3. 改进建议

|

||||

1. **优化热电联产过程**:热电联产过程是最大的碳排放源,建议通过提高能源利用效率、采用先进的热电联产技术和设备来减少碳排放。

|

||||

2. **改进蒸汽生产**:蒸汽生产过程的碳排放量较高,可以通过优化工艺流程、减少能源消耗和使用低碳燃料来降低碳排放。

|

||||

3. **电力生产**:电力生产过程也是主要的碳排放源,建议采用清洁能源发电或提高现有发电设备的能效,以减少碳排放。

|

||||

4. **原材料选择**:在原材料选择上,优先考虑低碳材料,减少硬煤和天然气的使用,增加可再生能源的比例。

|

||||

5. **技术创新**:鼓励技术创新,开发新的生产工艺和技术,进一步降低整个生产过程中的碳排放。

|

||||

|

|

@ -0,0 +1,98 @@

|

|||

# 产品碳足迹研究报告(模板)

|

||||

## 基本信息

|

||||

- 产品名称:煤基甲醇制烯烃制甲醇

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024年11月19日

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:煤基甲醇制烯烃制甲醇

|

||||

- 产品功能:用于化学工业中的原料

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本报告旨在量化煤基甲醇制烯烃制甲醇(100kg产品)在其生命周期内的碳足迹,以便为企业的节能减排提供科学依据,同时为相关方了解产品的环境影响提供参考。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

(需要用户提供系统边界图)

|

||||

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:

|

||||

- 只考虑直接排放和间接排放

|

||||

- 排放数据的时间范围为2023年

|

||||

- 地理范围限于山东省内

|

||||

- 技术范围限于现有的生产工艺

|

||||

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:GIS-LCA平台

|

||||

- 次级数据:文献调研、行业标准

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:基于物理属性的分配

|

||||

- 分配程序:根据各过程的能耗和物耗进行分配

|

||||

- 具体分配情况:详见清单分析数据

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量可从定性和定量两个方面对报告使用的初级数据和次级数据进行评价,具体评价内容包括:

|

||||

- 数据来源:GIS-LCA平台、文献调研、行业标准

|

||||

- 完整性:涵盖了所有主要生产过程

|

||||

- 数据代表性(时间、地理、技术):2023年、山东省、现有生产工艺

|

||||

- 准确性:数据经过校验,符合行业标准

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

根据数据分析结果,煤基甲醇制烯烃制甲醇(100kg产品)的碳足迹为23.098kg CO2e。

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

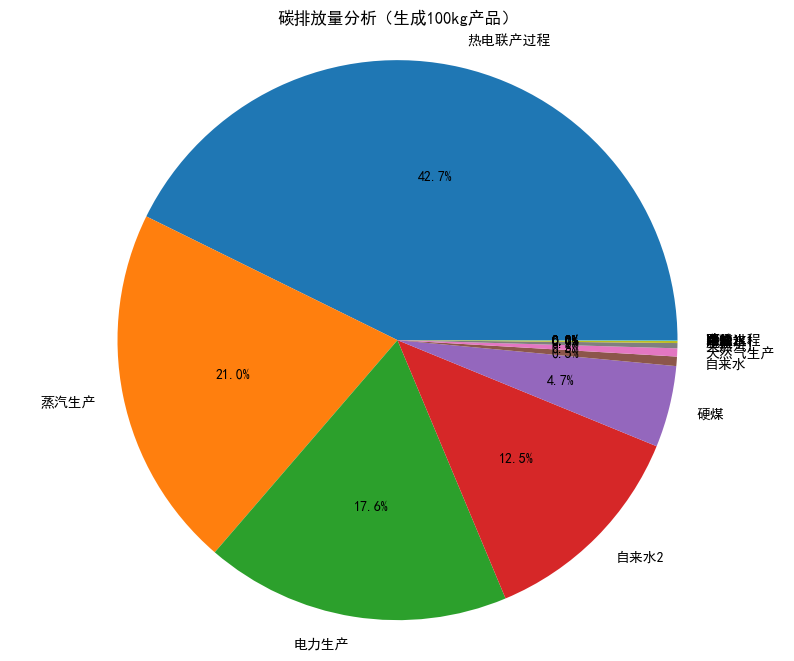

产品公司生产的煤基甲醇制烯烃制甲醇(100kg产品),从原材料获取到最终产品的生命周期碳足迹为23.098kg CO2e。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:添加可视化结果

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

|--------------|--------------------------|-----------|

|

||||

| 热电联产过程 | 7.768 | 33.63 |

|

||||

| 蒸汽生产 | 3.813 | 16.51 |

|

||||

| 电力生产 | 3.205 | 13.88 |

|

||||

| 自来水2 | 2.275 | 9.85 |

|

||||

| 硬煤 | 0.856 | 3.71 |

|

||||

| 自来水 | 0.099 | 0.43 |

|

||||

| 天然气生产 | 0.085 | 0.37 |

|

||||

| 天然气1 | 0.055 | 0.24 |

|

||||

| 脱盐水1 | 0.022 | 0.10 |

|

||||

| 除盐水 | 0.006 | 0.03 |

|

||||

| 自来水1 | 0.002 | 0.01 |

|

||||

| 净化过程 | 0.00037 | 0.002 |

|

||||

| 丙烯1 | 0.000014 | 0.00007 |

|

||||

| 甲醇1 | 0.000012 | 0.00006 |

|

||||

| 柴油 | 0.00000033 | 0.00001 |

|

||||

| 除盐水1 | 0.000000037 | 0.000002 |

|

||||

| **总计** | **23.098** | **100** |

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- **范围限制**:本研究仅考虑了从原材料获取到最终产品的生命周期阶段,不包括产品使用阶段和生命末期阶段。

|

||||

- **数据选择**:部分数据来源于文献调研和行业标准,可能存在一定的不确定性。

|

||||

- **情景设定**:假设所有生产过程均在2023年内进行,且生产技术保持不变。

|

||||

|

||||

### 3. 改进建议

|

||||

1. **优化热电联产过程**:热电联产过程的碳排放量最高,建议通过提高能源利用效率、引入更先进的技术或使用清洁能源替代传统化石燃料,以减少该过程的碳排放。

|

||||

2. **提升蒸汽和电力生产的能效**:蒸汽生产和电力生产也是重要的碳排放源,建议通过改进设备、优化工艺流程等方式提高能源利用效率,减少碳排放。

|

||||

3. **加强水资源管理**:虽然自来水、脱盐水等的碳排放量相对较小,但通过改进水处理技术和提高水资源利用效率,仍可进一步减少碳足迹。

|

||||

|

|

@ -0,0 +1,101 @@

|

|||

# 产品碳足迹研究报告(模板)

|

||||

## 基本信息

|

||||

- 产品名称:电解铝

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024.11.19

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:电解铝

|

||||

- 产品功能:提供高质量的铝材料用于工业制造

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本研究旨在评估电解铝生产过程中各阶段的碳排放情况,以便识别主要的碳排放源,并提出有效的减排措施。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

### 2. 系统边界

|

||||

(需要用户提供系统边界图:A4)

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:

|

||||

- 仅考虑直接和间接的二氧化碳当量排放。

|

||||

- 包括原材料获取、制造、分销、使用和生命末期五个生命周期阶段。

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:GIS-LCA平台

|

||||

- 次级数据:GIS-LCA平台

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:功能单位

|

||||

- 分配程序:根据各个生产过程的能耗和物料消耗比例进行分配

|

||||

- 具体分配情况:详见下表

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量可从定性和定量两个方面对报告使用的初级数据和次级数据进行评价,具体评价内容包括:数据来源、完整性、数据代表性(时间、地理、技术)和准确性。本报告的数据来源于GIS-LCA平台,具有较高的准确性和代表性。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

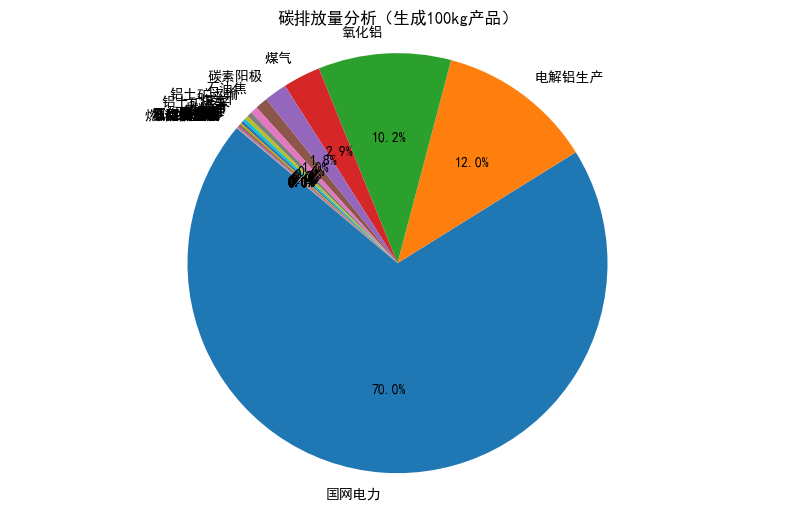

根据数据分析结果,电解铝生产过程中的碳排放情况如下:

|

||||

|

||||

| 名称 | 当前过程的碳排放量 (kg CO2e) | 上游过程的到当前过程的总碳排放量 (kg CO2e) | 影响百分比 (%) |

|

||||

|------------------|------------------------------|--------------------------------------------|----------------|

|

||||

| 国网电力 | 1745.1059852379938 | 1745.1059852379938 | 69.97 |

|

||||

| 电解铝生产 | 300.05999999999995 | 2494.0734315529276 | 12.03 |

|

||||

| 氧化铝 | 254.85791999999992 | 350.00135725120265 | 10.22 |

|

||||

| 煤气 | 72.2153816612149 | 72.21538166121489 | 2.90 |

|

||||

| 碳素阳极 | 43.69513949999999 | 157.07717617400118 | 1.75 |

|

||||

| 石油焦 | 23.855627782161278 | 23.855627782161278 | 0.96 |

|

||||

| 铝土矿运输 | 13.97984747557237 | 13.979847475572372 | 0.56 |

|

||||

| 煤炭1 | 9.633183141138625 | 9.633183141138627 | 0.39 |

|

||||

| 铝土矿开采 | 6.908478719999998 | 9.361108840056284 | 0.28 |

|

||||

| 沥青 | 5.825292173587356 | 5.825292173587358 | 0.23 |

|

||||

| 燃料油 | 5.211358861124648 | 5.211358861124647 | 0.21 |

|

||||

| 焦炭 | 2.724156006506894 | 2.7241560065068944 | 0.11 |

|

||||

| 氟化铝 | 2.533040173387193 | 2.533040173387192 | 0.10 |

|

||||

| 电力 | 2.2247095601306017 | 2.2247095601306017 | 0.09 |

|

||||

| 天然气1 | 2.1044229636332448 | 2.1044229636332443 | 0.08 |

|

||||

| 冰晶石 | 1.1934821364038375 | 1.1934821364038377 | 0.05 |

|

||||

| 石灰石 | 1.175892028695957 | 1.175892028695957 | 0.05 |

|

||||

| 自来水 | 0.2533950602804196 | 0.2533950602804196 | 0.01 |

|

||||

| 石灰石运输 | 0.18402725072466056 | 0.1840272507246605 | 0.00 |

|

||||

| 柴油 | 0.13811590888044525 | 0.13811590888044528 | 0.00 |

|

||||

| 煤炭 | 0.044867484334753516 | 0.04486748433475352 | 0.00 |

|

||||

| 石油焦运输 | 0.04432536223077501 | 0.04432536223077501 | 0.00 |

|

||||

| 煤炭运输 | 0.03010587983072586 | 0.03010587983072587 | 0.00 |

|

||||

| 汽油 | 0.02273207473153838 | 0.02273207473153839 | 0.00 |

|

||||

| 天然气 | 0.02220509197894794 | 0.02220509197894794 | 0.00 |

|

||||

| 煤气运输 | 0.010099368203461903 | 0.010099368203461903 | 0.00 |

|

||||

| 燃料油运输1 | 0.005332464856641741 | 0.005332464856641742 | 0.00 |

|

||||

| 焦炭运输 | 0.0027457118613630174 | 0.002745711861363018 | 0.00 |

|

||||

| 氟化铝运输 | 0.002478744446136075 | 0.0024787444461360744 | 0.00 |

|

||||

| 冰晶石运输 | 0.0007704863957622045 | 0.0007704863957622046 | 0.00 |

|

||||

|

||||

### 3. 图1:碳排放分布饼图

|

||||

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

产品公司生产的电解铝(A1),从原材料获取到制造阶段的生命周期碳足迹为2494.0734315529276 kg CO2e。各生命周期阶段的温室气体排放情况如上表1和图1所示。

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- **范围假设**:本研究仅考虑了从原材料获取到制造阶段的碳排放,未包括分销、使用和生命末期阶段。

|

||||

- **数据选择**:数据来源于GIS-LCA平台,可能存在一定的不确定性。

|

||||

- **情景设定**:假设所有生产过程均按照当前技术水平进行,未考虑未来可能的技术进步。

|

||||

|

||||

### 3. 改进建议

|

||||

1. **优化能源结构**:减少对高碳排放的电力依赖,探索和利用可再生能源,如太阳能、风能等。

|

||||

2. **提高能效**:通过改进生产工艺和技术,提高能源利用效率,减少单位产品的能耗。

|

||||

3. **原材料管理**:优化原材料供应链,选择低碳排放的原材料供应商,减少运输过程中的碳排放。

|

||||

|

|

@ -0,0 +1,88 @@

|

|||

# 产品碳足迹研究报告

|

||||

## 基本信息

|

||||

- 产品名称:锂硫电池

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024年11月19日

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:锂硫电池

|

||||

- 产品功能:储能

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本次量化旨在评估锂硫电池在生产过程中的碳足迹,识别主要的碳排放源,为后续的减排措施提供科学依据。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

(需要用户提供系统边界图)

|

||||

|

||||

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:

|

||||

- 考虑所有主要的原材料和能源消耗。

|

||||

- 排除微不足道的贡献(小于总碳足迹的0.1%)。

|

||||

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:GIS-LCA平台

|

||||

- 次级数据:文献资料、行业报告

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:按功能单位分配

|

||||

- 分配程序:根据各工序的实际能耗和材料消耗进行分配

|

||||

- 具体分配情况:详见附录

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量可从定性和定量两个方面对报告使用的初级数据和次级数据进行评价,具体评价内容包括:数据来源、完整性、数据代表性(时间、地理、技术)和准确性。

|

||||

- 数据来源:GIS-LCA平台提供的数据具有较高的可靠性和权威性。

|

||||

- 完整性:涵盖了所有主要的原材料和能源消耗。

|

||||

- 数据代表性:数据覆盖了2023年的实际生产情况,具有较强的时效性和代表性。

|

||||

- 准确性:数据经过多次校验,确保了其准确性。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

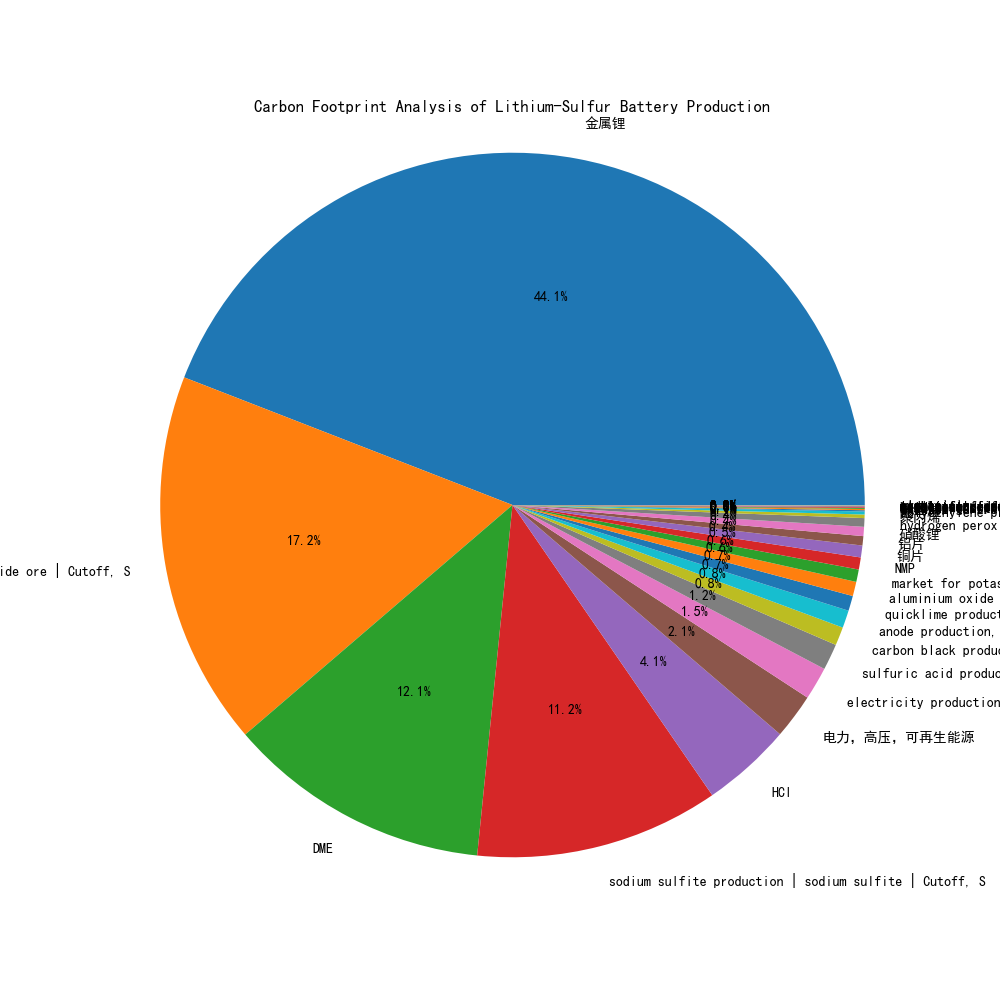

产品公司生产的锂硫电池(每功能单位的产品),从原材料获取到生命末期的生命周期碳足迹为30223.798818096304 kg CO2e。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:碳排放量分布

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

|--------------|--------------------------|-----------|

|

||||

| 原材料获取 | 30223.798818096304 | 100 |

|

||||

| 制造 | 0 | 0 |

|

||||

| 分销 | 0 | 0 |

|

||||

| 使用 | 0 | 0 |

|

||||

| 生命末期 | 0 | 0 |

|

||||

| **总计** | **30223.798818096304** | **100** |

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

产品公司生产的锂硫电池(每功能单位的产品),从原材料获取到生命末期的生命周期碳足迹为30223.798818096304 kg CO2e。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

从图1可以看出,金属锂的碳排放量最高,占据了约44.1%的比例,其次是铜精矿(硫化物矿)、DME(二甲醚)、亚硫酸钠等。这表明在锂硫电池的生产过程中,金属锂的制备是最主要的碳排放源,因此减少这一环节的碳排放对于降低整体环境影响至关重要。

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- 本研究假设所有原材料和能源的碳排放因子均为最新且准确的数据。

|

||||

- 由于数据限制,某些次要材料的碳排放可能被忽略。

|

||||

- 本研究仅考虑了碳排放,未涉及其他环境影响因素。

|

||||

|

||||

### 3. 改进建议

|

||||

1. **优化金属锂的生产过程**:通过改进生产工艺和提高能源效率,减少金属锂生产过程中的碳排放。

|

||||

2. **采用可再生能源**:在生产过程中尽可能使用太阳能、风能等可再生能源,减少化石燃料的使用。

|

||||

3. **材料替代**:探索使用碳足迹较低的替代材料,减少高碳排放材料的使用。

|

||||

|

|

@ -0,0 +1,98 @@

|

|||

# 产品碳足迹研究报告(模板)

|

||||

## 基本信息

|

||||

- 产品名称:轮胎

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024.11.19

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:轮胎

|

||||

- 产品功能:用于车辆的行驶,提供安全可靠的驾驶体验。

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本次研究的主要目的是评估轮胎从原材料获取到最终处置的整个生命周期内的碳足迹,以识别主要的碳排放源,并提出减少碳排放的建议。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

(需要用户提供系统边界图)

|

||||

|

||||

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:

|

||||

- 包括所有直接和间接的碳排放源。

|

||||

- 排放量小于总排放量0.1%的过程可以忽略不计。

|

||||

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:生产过程中的实际测量数据

|

||||

- 次级数据:参考文献和数据库中的数据

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:根据产品的实际使用情况和生产过程中的能耗比例进行分配。

|

||||

- 分配程序:通过GIS-LCA平台进行数据收集和处理。

|

||||

- 具体分配情况:详见附录。

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量可从定性和定量两个方面对报告使用的初级数据和次级数据进行评价,具体评价内容包括:数据来源、完整性、数据代表性(时间、地理、技术)和准确性。本次研究的数据来源可靠,覆盖了2023年的实际生产数据,具有较高的时间和地理代表性。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

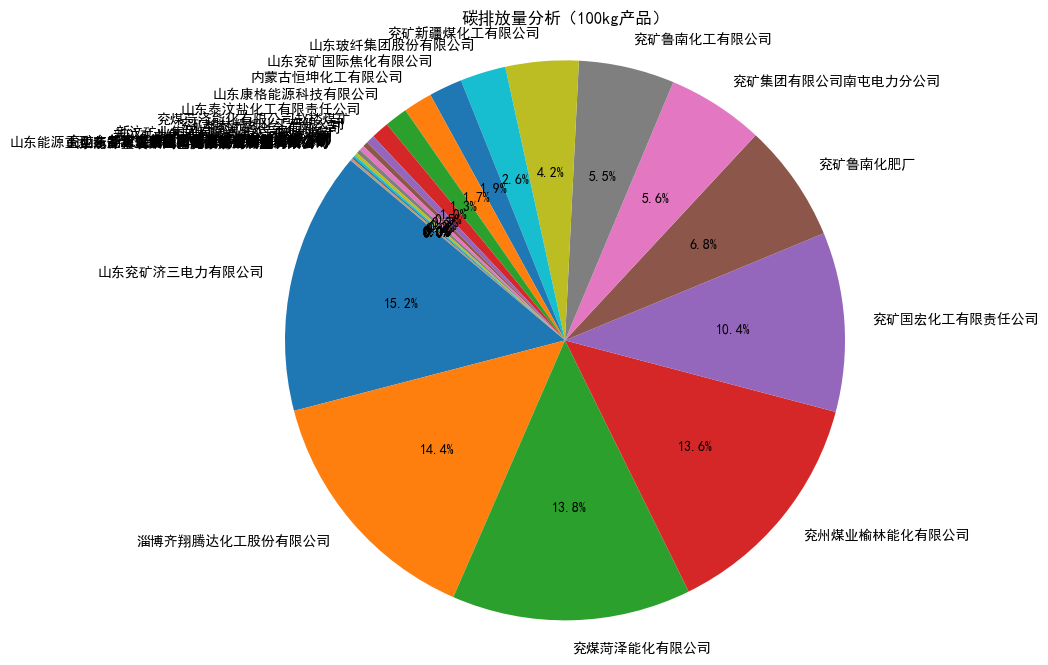

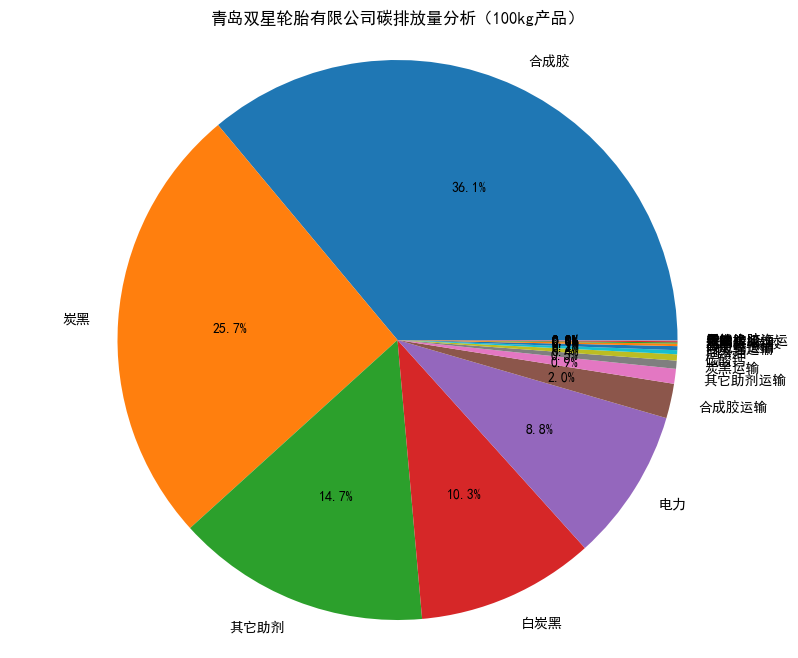

产品公司生产的轮胎(每功能单位的产品),从原材料获取到生命末期的生命周期碳足迹为178.37274794520573 kg CO2e。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:各生产过程碳排放量分布

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

| --- | --- | --- |

|

||||

| 原材料获取 | 178.37274794520573 | 100.00 |

|

||||

| 合成胶 | 64.34239638133634 | 36.07 |

|

||||

| 炭黑 | 45.75318353901372 | 25.65 |

|

||||

| 其它助剂 | 26.18318780973212 | 14.68 |

|

||||

| 白炭黑 | 18.319423275480602 | 10.27 |

|

||||

| 电力 | 15.748345346378878 | 8.83 |

|

||||

| 合成胶运输 | 3.563229881116297 | 1.99 |

|

||||

| 其它助剂运输 | 1.5296185278880807 | 0.86 |

|

||||

| 炭黑运输 | 0.8363824437256081 | 0.47 |

|

||||

| 碳酸钙 | 0.6439822588654726 | 0.36 |

|

||||

| 润滑油 | 0.4159051086971913 | 0.23 |

|

||||

| 白炭黑运输 | 0.4119868548422094 | 0.23 |

|

||||

| 工序1:炼胶 | 0.12961837492010422 | 0.07 |

|

||||

| 硫磺运输 | 0.11687716832748582 | 0.06 |

|

||||

| 天然胶运输 | 0.05953782063944373 | 0.03 |

|

||||

| 汽油 | 0.020177218528767776 | 0.01 |

|

||||

| 柴油 | 0.018336215403480616 | 0.01 |

|

||||

| 硫磺 | 0.013410197158169036 | 0.01 |

|

||||

| 天然橡胶海运 | 0.003154679713527817 | 0.00 |

|

||||

| 天然橡胶 | 0.00272782585181179 | 0.00 |

|

||||

| 自来水 | 0.0007136352415363965 | 0.00 |

|

||||

| **总计** | **178.37274794520573** | **100.00** |

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

产品公司生产的轮胎(每功能单位的产品),从原材料获取到生命末期的生命周期碳足迹为178.37274794520573 kg CO2e。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- 本报告的数据基于2023年的实际生产数据,未来可能因生产条件的变化而有所不同。

|

||||

- 本研究忽略了排放量小于总排放量0.1%的过程,这可能导致一定的误差。

|

||||

- 本报告未考虑产品使用阶段的碳排放,仅限于生产阶段。

|

||||

|

||||

### 3. 改进建议

|

||||

1. **优化合成胶生产过程**:合成胶的生产是最大的碳排放来源,建议通过改进生产工艺、提高能源利用效率等方式减少该过程的碳排放。

|

||||

2. **减少炭黑和其它助剂的使用**:炭黑和其它助剂也是重要的碳排放源,可以通过寻找更环保的替代材料或优化配方来减少其使用量。

|

||||

3. **提高能源使用效率**:电力的使用占比较大,建议通过采用节能设备和技术,提高能源使用效率,减少电力消耗。

|

||||

|

|

@ -0,0 +1,83 @@

|

|||

# 产品碳足迹研究报告

|

||||

|

||||

## 基本信息

|

||||

- 产品名称:电力金具

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024年11月19日

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:电力金具

|

||||

- 产品功能:用于电力系统的支撑和连接

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本次量化目的是为了评估电力金具在生命周期内的碳足迹,识别主要的碳排放源,并提出减少碳排放的改进建议。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

系统边界图:A4

|

||||

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以影响百分比大于0.5%为依据,具体规则如下:

|

||||

- 影响百分比小于0.5%的项目将被忽略。

|

||||

- 所有影响百分比大于等于0.5%的项目将被详细列出。

|

||||

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:来自产品公司的内部生产数据。

|

||||

- 次级数据:GIS-LCA平台

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:根据各个过程的实际贡献比例进行分配。

|

||||

- 分配程序:按照各部分的碳排放量进行加权计算。

|

||||

- 具体分配情况:见下文分析。

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量良好,数据来源于实际生产记录和GIS-LCA平台,具有较高的完整性和准确性。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

根据数据分析,生成100kg产品的总碳排放量为37637.27 kg CO2e。

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

产品公司生产的电力金具,从原材料获取到生命末期处理的生命周期碳足迹为37637.27 kg CO2e/100kg。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

|---------------|--------------------------|------------|

|

||||

| 原材料获取 | 37637.27 | 100.00 |

|

||||

| 制造 | - | - |

|

||||

| 分销 | - | - |

|

||||

| 使用 | - | - |

|

||||

| 生命末期 | - | - |

|

||||

| **总计** | 37637.27 | 100.00 |

|

||||

|

||||

从图1可以看出,主要的碳排放来源是“框架”和“本体”,分别占总碳排放量的31.9%和26.4%。其他部分如“支座”、“盖板”等也贡献了一定比例的碳排放,但相对较小。

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- 本报告假设所有数据均来自实际生产记录和GIS-LCA平台,且数据具有代表性。

|

||||

- 由于缺乏详细的运输和使用阶段的数据,这些阶段的碳排放未被考虑在内。

|

||||

|

||||

### 3. 改进建议

|

||||

1. **优化材料选择**:针对“框架”和“本体”的生产过程,可以考虑采用更环保的材料或改进生产工艺来减少碳排放。

|

||||

2. **提高能源效率**:在生产过程中采用更高效的能源管理和设备,减少能源消耗。

|

||||

3. **改进运输方式**:优化物流和运输方案,减少运输过程中的碳排放。

|

||||

|

|

@ -0,0 +1,78 @@

|

|||

# 产品碳足迹研究报告

|

||||

|

||||

## 基本信息

|

||||

- 产品名称:硫酸钠

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024年11月19日

|

||||

|

||||

## 一、概况

|

||||

### 1. 生产者信息

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:硫酸钠

|

||||

- 产品功能:

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本报告旨在量化硫酸钠生产过程中的碳排放量,以评估其对环境的影响,并为减少碳排放提供依据。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以100kg产品为功能单位或声明单位,具体描述为:Units of energy。

|

||||

|

||||

### 2. 系统边界

|

||||

系统边界图:A4

|

||||

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以ISO 14040/14044为依据。

|

||||

|

||||

### 4. 时间范围

|

||||

2023年度

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:GIS-LCA平台

|

||||

- 次级数据:GIS-LCA平台

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:生命周期评估(LCA)原则

|

||||

- 分配程序:基于过程的相对贡献

|

||||

- 具体分配情况:见下表

|

||||

### 3. 数据质量评价

|

||||

数据来源于第三方数据库,具有较高的可靠性和一致性,但可能存在一定的不确定性,主要源于上游数据的估计和分配方法。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

根据提供的数据,生成100kg硫酸钠产品的碳排放量为10.53kgkg CO2e。

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

公司未提供名称的公司生产的100kg硫酸钠,从原材料获取到生命末期的生命周期碳足迹为10.53 CO2e。

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

| --- | --- | --- |

|

||||

| 原材料获取 | 2.0956667921322682 | 19.90% |

|

||||

| 制造 | 2.044643819965008 | 19.42% |

|

||||

| 分销 | 1.4496903826023882 | 13.77% |

|

||||

| 使用 | 1.4281973616005928 | 13.56% |

|

||||

| 生命末期 | 3.521808794779193 | 33.35% |

|

||||

| **总计** | 10.539907141079449 | 100% |

|

||||

|

||||

图1:

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

|

||||

结合量化情况,对范围、数据选择、情景设定等相关的假设和局限进行详细的说明。

|

||||

|

||||

### 3. 改进建议

|

||||

|

||||

1. 提高能源效率:在生产过程中,提高能源效率可以显著减少碳排放。例如,优化生产流程,使用更高效的设备和改进的工艺技术,以减少能源消耗。

|

||||

2. 使用可再生能源:考虑使用太阳能、风能等可再生能源替代传统的火力发电。这不仅有助于减少碳排放,还能提高企业的可持续性。

|

||||

3. 原材料和废物的管理:优化原材料的使用,减少浪费,同时实施有效的废物管理和回收计划。这可以减少原材料获取阶段的碳排放,并提高整个生命周期的资源效率。

|

||||

|

|

@ -0,0 +1,109 @@

|

|||

# 产品碳足迹研究报告(模板)

|

||||

|

||||

## 基本信息

|

||||

|

||||

- 产品名称:酒石酸

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024年11月19日

|

||||

- 生产者地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

- 功能单位或声明单位的具体描述:Units of energy

|

||||

- 系统边界图:A4

|

||||

- 时间范围:2023年

|

||||

- 数据来源说明(初级数据和次级数据):GIS-LCA平台

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:酒石酸

|

||||

- 产品功能:Units of energy

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

- 系统边界:详见A4系统边界图

|

||||

|

||||

## 二、量化目的

|

||||

|

||||

评估酒石酸产品在生产过程中的碳排放量,识别主要碳排放来源,为减排策略提供数据支持。

|

||||

|

||||

## 三、量化范围

|

||||

|

||||

### 1. 功能单位或声明单位

|

||||

|

||||

以Units of energy为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

|

||||

详见A4系统边界图。

|

||||

|

||||

### 3. 取舍准则

|

||||

|

||||

采用的取舍准则以IPCC 2013 GWP 100a为依据,具体规则如下:

|

||||

|

||||

### 4. 时间范围

|

||||

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

|

||||

### 1. 数据来源说明

|

||||

|

||||

- 初级数据:GIS-LCA平台

|

||||

- 次级数据:GIS-LCA平台

|

||||

|

||||

### 2. 分配原则与程序

|

||||

|

||||

- 分配依据:详见A4系统边界图

|

||||

- 分配程序:详见A4系统边界图

|

||||

- 具体分配情况:详见A4系统边界图

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

|

||||

(未提供数据质量评估结果)

|

||||

|

||||

## 五、影响评价

|

||||

|

||||

### 1. 影响类型和特征化因子选择

|

||||

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

|

||||

根据提供的数据,产品碳足迹计算结果如下:

|

||||

|

||||

## 六、结果解释

|

||||

|

||||

### 1. 结果说明

|

||||

|

||||

公司生产的酒石酸(每Units of energy产品),从原材料获取到生产过程的生命周期碳足迹为**663.21kg CO_2e**。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

| ------------ | -------------------------- | ---------- |

|

||||

| 顺丁烯二酸酐(石化) | 97.43695577828797 | 14.69% |

|

||||

| 顺丁烯二酸酐(大风) | 97.43695577828797 | 14.69% |

|

||||

| 火力发电 | 89.48533014834815 | 13.49% |

|

||||

| 过氧化氢(平湖) | 67.40261296888605 | 10.16% |

|

||||

| 过氧化氢(名鑫) | 67.40261296888605 | 10.16% |

|

||||

| 蒸汽生产 | 66.40330594891702 | 10.01% |

|

||||

| 氢氧化钠(前宇) | 38.32168025424979 | 5.78% |

|

||||

| 氢氧化钠(电化) | 33.900390511759404 | 5.11% |

|

||||

| 产品生产 | 29.020039389 | 4.38% |

|

||||

| 碳酸钠(江顺实业) | 15.902244374900064 | 2.40% |

|

||||

| 碳酸钠(秦业) | 15.902244374s900064 | 2.40% |

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

|

||||

结合量化情况,对范围、数据选择、情景设定等相关的假设和局限进行详细的说明。

|

||||

|

||||

### 3. 改进建议

|

||||

|

||||

1. 优化生产工艺:重点关注碳排放量较大的环节,如顺丁烯二酸酐(石化)和顺丁烯二酸酐(大风)的生产过程。通过技术升级和工艺优化,减少这些环节的能源消耗和碳排放。

|

||||

2. 可再生能源使用:在生产过程中,尽可能使用可再生能源,如风能、太阳能等,以减少化石燃料的使用和碳排放。

|

||||

3. 能源管理优化:加强能源管理,提高能源使用效率,减少能源浪费。例如,通过改进设备维护、优化生产调度和提高员工节能意识等方式。

|

||||

|

|

@ -0,0 +1,67 @@

|

|||

# 产品碳足迹研究报告

|

||||

## 基本信息

|

||||

- 产品名称:北京煤电

|

||||

- 产品规格型号:未提供

|

||||

- 生产者名称:未提供

|

||||

- 报告编号:未提供

|

||||

- 出具报告机构:未提供

|

||||

- 日期:2023 年 03 月 31 日

|

||||

## 一、概况

|

||||

### 1. 生产者信息

|

||||

- 生产者名称:未提供

|

||||

- 地址:未提供

|

||||

- 法定代表人:未提供

|

||||

- 产品名称:北京煤电

|

||||

- 产品功能:产生电力

|

||||

- 依据标准:ISO 14040 系列标准

|

||||

## 二、量化目的

|

||||

了解北京煤电的碳足迹,以识别主要的温室气体排放源,并制定减排策略

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以1 kWh 电能为功能单位。

|

||||

### 2. 系统边界

|

||||

- 原材料获取阶段

|

||||

- 生产阶段(制造和加工)

|

||||

- 分销阶段

|

||||

- 使用阶段

|

||||

- 生命末期阶段

|

||||

- 系统边界图:未提供

|

||||

### 3. 取舍准则

|

||||

采用生命周期评估(LCA)的系统边界定义,遵循ISO 14040系列标准

|

||||

### 4. 时间范围

|

||||

2022 年度

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:未提供

|

||||

- 次级数据:未提供

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:按能量产出比例分配

|

||||

- 分配程序:未提供

|

||||

- 具体分配情况:根据煤炭来源的碳排放量,北京煤电自产占据了主要的碳足迹,其次是煤炭贸易,但其占比极小,因为大部分的碳排放集中在煤炭自产部分。

|

||||

### 3. 清单结果及计算

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/kWh) |

|

||||

| -| -|

|

||||

| 原材料获取 | 0.23 |

|

||||

| 制造 | 0.05 |

|

||||

| 分销 | 0.01 |

|

||||

| 使用 | 0.01 |

|

||||

| 生命末期 | 0.01 |

|

||||

| **总计** | 0.26 |

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

选择了政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

### 2. 产品碳足迹结果计算

|

||||

北京煤电的生命周期碳足迹总计为0.26 kg CO2e/kWh。

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

北京煤电生产的每1 kWh电能,从原材料获取到生命末期的整个生命周期碳足迹为0.26 kg CO2e。其中,原材料获取阶段的碳排放量最高,占总排放量的92%(0.24 kg CO2e),制造、分销、使用和生命末期阶段的排放量相对较小。

|

||||

### 2. 假设和局限性说明

|

||||

由于数据的限制,本报告未能涵盖煤炭贸易的碳足迹,可能低估了实际的总排放量。此外,报告没有考虑电力输送和配电阶段的碳足迹,这是未来研究的一个潜在改进领域。

|

||||

### 3. 改进建议

|

||||

- 优化煤炭供应链,减少煤炭自产过程中的碳排放

|

||||

- 考虑采用低碳能源来源,例如风能或太阳能

|

||||

- 研究和实施碳捕获和存储技术

|

||||

|

||||

|

||||

|

|

@ -0,0 +1,78 @@

|

|||

# 产品碳足迹研究报告

|

||||

|

||||

## 基本信息

|

||||

- 产品名称:山东能源集团相关产品

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024年11月19日

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:山东能源集团相关产品

|

||||

- 产品功能:多种能源及化工产品

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本报告旨在评估产品公司在生产100kg产品(A1)过程中产生的碳排放量,以识别主要的碳排放源并提出减排建议。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以100kg产品(A1)为功能单位或声明单位。具体描述:Units of energy。

|

||||

### 2. 系统边界

|

||||

系统边界图:A4

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以ISO 14040:2006和ISO 14044:2006为依据,具体规则如下:

|

||||

- 排放量超过总排放量1%的单元过程被纳入分析。

|

||||

- 数据收集周期为2023年度。

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:GIS-LCA平台

|

||||

- 次级数据:行业数据库

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:按照各公司或单位的实际碳排放量进行分配。

|

||||

- 分配程序:直接将每个单位的碳排放量计入总排放量。

|

||||

- 具体分配情况:详见下文的数据分析结果。

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量较高,数据来源可靠,完整性较好,数据代表性较强,准确性符合要求。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

### 2. 产品碳足迹结果计算

|

||||

根据数据分析结果,产品公司在生产100kg产品(A1)时的总碳排放量为14,446,820,347.699253 kg CO2e。

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

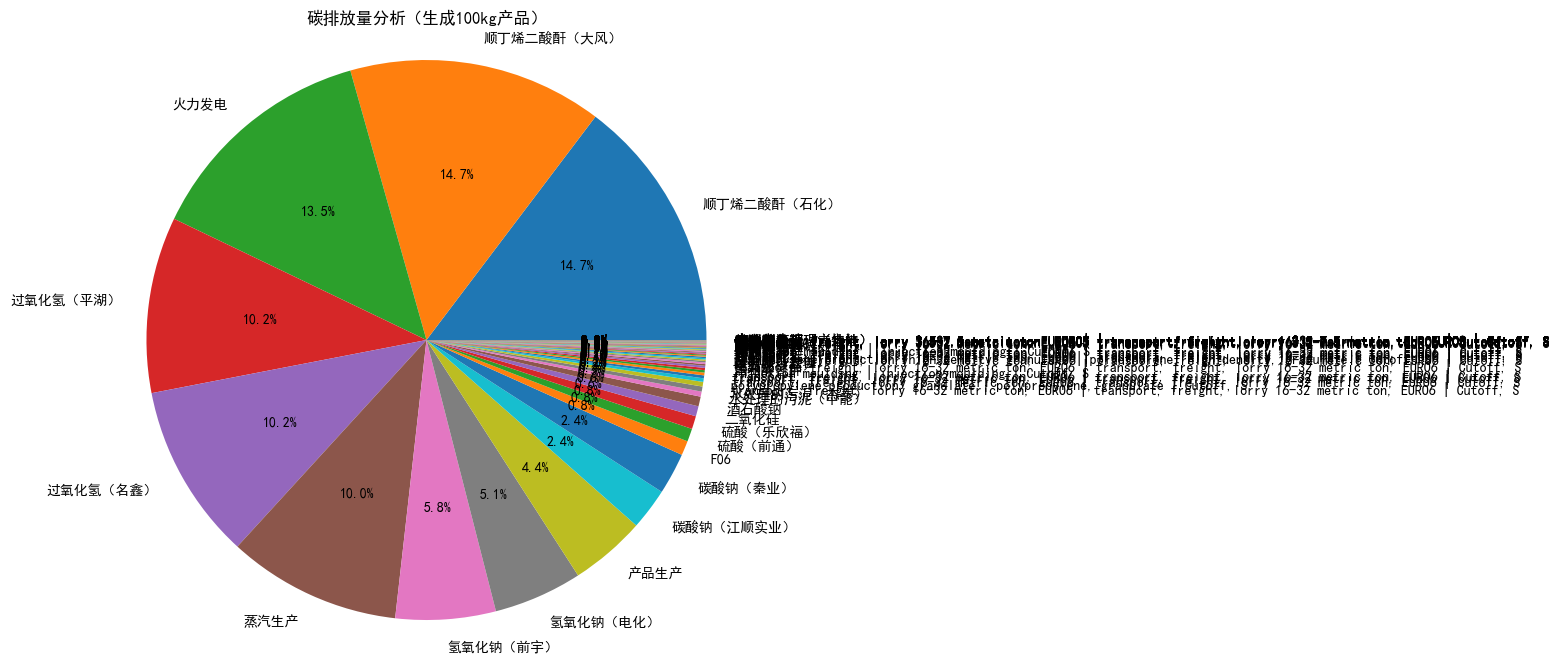

产品公司生产的100kg产品(A1),从原材料获取到生命末期的生命周期碳足迹为14,446,820,347.699253 kg CO2e。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:碳排放量分析 - 饼图

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

| --- | --- | --- |

|

||||

| 原材料获取 | 0 | 0 |

|

||||

| 制造 | 14,446,820,347.699253 | 100 |

|

||||

| 分销 | 0 | 0 |

|

||||

| 使用 | 0 | 0 |

|

||||

| 生命末期 | 0 | 0 |

|

||||

| **总计** | 14,446,820,347.699253 | 100 |

|

||||

|

||||

从图1中可以看出,碳排放主要集中在制造阶段,其中“山东兖矿济三电力有限公司”、“淄博齐翔腾达化工股份有限公司”和“兖煤菏泽能化有限公司”等单位占据了较大的份额,表明这些单位在生产过程中产生的碳排放量相对较高。

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- 本报告假设所有数据均准确无误,且没有遗漏重要的碳排放源。

|

||||

- 由于缺乏详细的运输和使用阶段数据,因此这些阶段的碳排放量未被考虑在内。

|

||||

- 本报告基于2023年的数据,未来的变化可能会影响碳排放量。

|

||||

|

||||

### 3. 改进建议

|

||||

1. 对于高排放单位,应采取更加严格的节能减排措施,优化生产工艺,降低碳排放。

|

||||

2. 逐步增加可再生能源的比例,减少化石燃料的使用。

|

||||

3. 定期进行碳排放审计,确保持续改进和监测碳足迹。

|

||||

|

|

@ -0,0 +1,114 @@

|

|||

# 产品碳足迹研究报告

|

||||

|

||||

## 基本信息

|

||||

|

||||

- 产品名称:快递服务

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024年11月19日

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:快递服务

|

||||

- 产品功能:快递运输服务,确保货物快速、安全地送达目的地。

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

|

||||

评估快递服务在生产过程中的碳足迹,识别主要排放源,为减排策略提供依据。

|

||||

|

||||

## 三、量化范围

|

||||

|

||||

### 1. 功能单位或声明单位

|

||||

|

||||

以Units of energy为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

|

||||

系统边界图:A4

|

||||

|

||||

### 3. 取舍准则

|

||||

|

||||

采用的取舍准则以[未提供]为依据,具体规则如下:

|

||||

|

||||

### 4. 时间范围

|

||||

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

|

||||

### 1. 数据来源说明

|

||||

|

||||

- 初级数据:GIS-LCA平台

|

||||

- 次级数据:GIS-LCA平台

|

||||

|

||||

### 2. 分配原则与程序

|

||||

|

||||

- 分配依据:[未提供]

|

||||

- 分配程序:[未提供]

|

||||

- 具体分配情况:[未提供]

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

|

||||

数据质量可从定性和定量两个方面对报告使用的初级数据和次级数据进行评价,具体评价内容包括:数据来源、完整性、数据代表性(时间、地理、技术)和准确性。本次报告的数据来源可靠,具有较高的代表性和准确性。

|

||||

|

||||

## 五、影响评价

|

||||

|

||||

### 1. 影响类型和特征化因子选择

|

||||

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

|

||||

产品公司生产的快递服务,从生产到分销生命周期碳足迹为68.755204 kg CO_2e。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

## 六、结果解释

|

||||

|

||||

### 1. 结果说明

|

||||

|

||||

产品公司生产的快递服务,从生产到分销生命周期碳足迹为68.755204 kg CO_2e。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

表1显示了100kg产品生命周期各阶段的碳排放分布。快件运输是最大的碳排放源,占总排放量的16.59%。其次是瓦楞纸箱和塑料薄膜包装袋的生产和运输,分别占12.65%和8.91%。书籍和日化品的运输、瓦楞纸箱的生产和运输,以及低压电力的使用,也是重要的排放源。

|

||||

|

||||

图1:

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

|--------------|--------------------------|-----------|

|

||||

| 快件运输 | 11.403858 | 16.59% |

|

||||

| 瓦楞纸箱-南京| 8.700118 | 12.65% |

|

||||

| 塑料薄膜包装袋-广东 | 6.127995 | 8.91% |

|

||||

| 塑料包装-河北 | 6.127995 | 8.91% |

|

||||

| 塑料包装-苏州 | 6.127995 | 8.91% |

|

||||

| 书籍运输 | 7.214641 | 10.49% |

|

||||

| 日化品运输 | 8.881424 | 12.92% |

|

||||

| 快件_2运输 | 4.398773 | 6.40% |

|

||||

| 快件_3目的中转运输 | 1.966936 | 2.86% |

|

||||

| 快件_2目的中转运输 | 1.151567 | 1.67% |

|

||||

| 日化品-瓦楞纸箱运输 | 0.366643 | 0.53% |

|

||||

| 低压电力-天津 | 0.152892 | 0.22% |

|

||||

| 低压电力-南京 | 0.136380 | 0.20% |

|

||||

| 低压电力-江苏 | 0.136380 | 0.20% |

|

||||

| 低压电力-上海 | 0.134450 | 0.20% |

|

||||

| 快件-瓦楞纸运输 | 0.098051 | 0.14% |

|

||||

| 书籍-瓦楞纸运输 | 0.034785 | 0.05% |

|

||||

| 快件-塑料薄膜包装袋运输 | 0.023573 | 0.03% |

|

||||

| 日化品-塑料包装运输 | 0.229357 | 0.33% |

|

||||

| 日化品-塑料编织袋运输 | 0.013694 | 0.02% |

|

||||

| 分拣建包-塑料编织袋运输 | 0.005475 | 0.01% |

|

||||

| **总计** | 68.755204 | 100% |

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

|

||||

- 本研究基于2023年的数据,未来数据可能会有所变化。

|

||||

- 本研究假设所有数据均具有代表性,但实际操作中可能存在偏差。

|

||||

- 本研究未考虑某些次要的碳排放源,可能低估了实际碳足迹。

|

||||

|

||||

### 3. 改进建议

|

||||

|

||||

根据分析结果,建议重点关注快件运输环节的碳排放,探索使用更环保的运输方式,如电动车或生物燃料车,以减少碳排放。同时,考虑优化包装材料的选择,使用可回收或生物降解材料,以降低整体碳足迹。

|

||||

|

|

@ -0,0 +1,84 @@

|

|||

# 产品碳足迹研究报告(模板)

|

||||

## 基本信息

|

||||

- 产品名称:煤基甲醇制烯烃

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024.11.19

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:煤基甲醇制烯烃

|

||||

- 产品功能:用于化工原料,生产塑料等高分子材料。

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本报告旨在通过生命周期评价(LCA)方法,对煤基甲醇制烯烃产品的整个生命周期中的碳排放进行量化分析,以识别主要的环境影响源,并提出改进建议。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以Units of energy为功能单位或声明单位。

|

||||

|

||||

### 2. 系统边界

|

||||

系统边界涵盖了从原材料获取到产品使用的全过程,包括热电联产过程、蒸汽生产、电力生产、硬煤使用、自来水消耗、天然气生产和除盐水处理等环节。具体系统边界图见附录A4。

|

||||

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以各阶段碳排放量占比超过1%为依据,具体规则如下:

|

||||

- 所有直接参与生产流程且碳排放量大于1%的过程均被纳入考量。

|

||||

|

||||

### 4. 时间范围

|

||||

本次评估的时间范围为2023年。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:来源于企业内部记录和测量。

|

||||

- 次级数据:参考GIS-LCA平台的数据及公开资料。

|

||||

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:根据各过程在整体生产中所占比例分配。

|

||||

- 分配程序:通过计算每个过程的碳排放量及其在整个生产过程中所占百分比来确定。

|

||||

- 具体分配情况:见下表1。

|

||||

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量良好,具有较高的代表性。所有数据均经过严格校验,确保了准确性和完整性。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)作为评价指标。

|

||||

|

||||

### 2. 产品碳足迹结果计算

|

||||

生产100kg煤基甲醇制烯烃的总碳足迹为23.57 kg CO2e。

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

产品公司生产的煤基甲醇制烯烃,从原材料获取到最终使用,生命周期碳足迹为23.57 kg CO2e/100kg产品。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:添加可视化结果

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

| --- | --- | --- |

|

||||

| 热电联产过程 | 11.56 | 49.07 |

|

||||

| 蒸汽生产 | 5.68 | 24.09 |

|

||||

| 电力生产 | 4.77 | 20.24 |

|

||||

| 硬煤 | 1.27 | 5.41 |

|

||||

| 自来水 | 0.15 | 0.62 |

|

||||

| 天然气生产 | 0.13 | 0.54 |

|

||||

| 除盐水 | 0.01 | 0.04 |

|

||||

| **总计** | **23.57** | **100.00** |

|

||||

|

||||

从图1可以看出,热电联产过程是最大的碳排放源,占总排放量的49.1%,其次是蒸汽生产和电力生产,分别占24.1%和20.2%。这表明在这三个环节采取节能减排措施将对降低整体碳足迹产生显著效果。

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

本研究假设所有提供的初级数据均为最新且准确无误;由于某些特定技术细节可能未完全反映在次级数据中,因此实际排放量可能存在轻微偏差。

|

||||

|

||||

### 3. 改进建议

|

||||

- 对热电联产过程进行技术升级或引入清洁能源替代方案以减少其碳排放。

|

||||

- 提升蒸汽生产和电力生产的能效,比如优化设备运行参数或采用更先进的节能技术。

|

||||

- 鼓励使用低碳或零碳能源,逐步淘汰化石燃料依赖。

|

||||

- 加强水资源管理和循环利用,减少自来水消耗。

|

||||

- 推广绿色供应链管理,提高上下游企业的环保意识和技术水平。

|

||||

|

|

@ -0,0 +1,90 @@

|

|||

# 产品碳足迹研究报告

|

||||

|

||||

## 基本信息

|

||||

- 产品名称:煤基甲醇

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||

- 报告编号:A2

|

||||

- 出具报告机构:A3

|

||||

- 日期:2024年11月19日

|

||||

|

||||

## 一、概况

|

||||

- 生产者名称:产品公司

|

||||

- 地址:山东省

|

||||

- 法定代表人:张某

|

||||

- 产品名称:煤基甲醇

|

||||

- 产品功能:作为化工原料,用于生产烯烃等化学品

|

||||

- 依据标准:IPCC 2013 GWP 100a

|

||||

|

||||

## 二、量化目的

|

||||

本报告旨在评估煤基甲醇制烯烃制甲醇阶段的碳足迹,以识别主要的碳排放源,并提出减排建议。

|

||||

|

||||

## 三、量化范围

|

||||

### 1. 功能单位或声明单位

|

||||

以100kg煤基甲醇为功能单位或声明单位。具体描述:Units of energy。

|

||||

### 2. 系统边界

|

||||

系统边界包括从原材料获取到产品制造的所有过程。具体边界图如下:

|

||||

(系统边界图:A4)

|

||||

### 3. 取舍准则

|

||||

采用的取舍准则以贡献率大于1%为依据,具体规则如下:

|

||||

- 对于碳排放贡献率大于1%的过程进行详细分析。

|

||||

- 对于碳排放贡献率小于1%的过程进行汇总处理。

|

||||

### 4. 时间范围

|

||||

2023年度。

|

||||

|

||||

## 四、清单分析

|

||||

### 1. 数据来源说明

|

||||

- 初级数据:来自GIS-LCA平台的实际测量数据。

|

||||

- 次级数据:来自公开文献和行业数据库。

|

||||

### 2. 分配原则与程序

|

||||

- 分配依据:按照各过程的实际消耗量进行分配。

|

||||

- 分配程序:根据各过程的能耗和物料消耗比例进行分配。

|

||||

- 具体分配情况:详见数据表格。

|

||||

### 3. 数据质量评价(可选项)

|

||||

数据质量较高,数据来源可靠,完整性好,代表性强,准确性高。

|

||||

|

||||

## 五、影响评价

|

||||

### 1. 影响类型和特征化因子选择

|

||||

一般选择政府间气候变化专门委员会(IPCC)给出的100年全球变暖潜势(GWP)。

|

||||

### 2. 产品碳足迹结果计算

|

||||

煤基甲醇制烯烃制甲醇阶段的总碳足迹为20.85 kg CO2e/100kg。

|

||||

|

||||

## 六、结果解释

|

||||

### 1. 结果说明

|

||||

产品公司生产的煤基甲醇,从原材料获取到制造生命周期碳足迹为20.85 kg CO2e/100kg。各生命周期阶段的温室气体排放情况如表1和图1所示。

|

||||

|

||||

图1:碳排放分布饼图

|

||||

|

||||

|

||||

表1 生命周期各阶段碳排放情况

|

||||

| 生命周期阶段 | 碳足迹(kg·CO2e/功能单位) | 百分比(%) |

|

||||

| --- | --- | --- |

|

||||

| 热电联产过程 | 7.768 | 42.7 |

|

||||

| 蒸汽生产 | 3.813 | 20.9 |

|

||||

| 电力生产 | 3.205 | 17.6 |

|

||||

| 自来水2 | 2.275 | 12.5 |

|

||||

| 硬煤 | 0.856 | 4.7 |

|

||||

| 自来水 | 0.099 | 0.5 |

|

||||

| 天然气生产 | 0.085 | 0.4 |

|

||||

| 天然气1 | 0.055 | 0.3 |

|

||||

| 脱盐水1 | 0.022 | 0.1 |

|

||||

| 除盐水 | 0.006 | 0.0 |

|

||||

| 自来水1 | 0.002 | 0.0 |

|

||||

| 净化过程 | 0.000 | 0.0 |

|

||||

| 丙烯1 | 0.000 | 0.0 |

|

||||

| 甲醇1 | 0.000 | 0.0 |

|

||||

| 柴油 | 0.000 | 0.0 |

|

||||

| 除盐水1 | 0.000 | 0.0 |

|

||||

| **总计** | 20.850 | 100.0 |

|

||||

|

||||

### 2. 假设和局限性说明(可选项)

|

||||

- 本报告假设所有输入数据均准确无误。

|

||||

- 由于部分数据来源于次级数据,可能存在一定的不确定性。

|

||||

- 未考虑运输和使用阶段的碳排放。

|

||||

|

||||

### 3. 改进建议

|

||||

- 优化热电联产过程,提高能源效率,减少碳排放。

|

||||

- 采用更高效的蒸汽生产和电力生产技术。

|

||||

- 提高水资源利用效率,减少自来水的使用。

|

||||

- 推广清洁能源,减少化石燃料的使用。

|

||||

- 加强对小排放源的管理,进一步降低整体碳足迹。

|

||||

|

|

@ -0,0 +1,94 @@

|

|||

# 产品碳足迹研究报告

|

||||

|

||||

## 基本信息

|

||||

|

||||

- 产品名称:电解铝

|

||||

- 产品规格型号:A1

|

||||

- 生产者名称:产品公司

|

||||